Fuel System

Fuel System Maintenance Mt Hope, Ohio

Regular maintenance of the fuel system is crucial for efficient engine performance. This includes periodic fuel filter replacements, fuel system cleanings, and using high-quality fuel to prevent clogging or damage to components. Any issues with the fuel system can result in poor engine performance, reduced fuel efficiency, and potential engine damage. Professional inspection and maintenance by qualified technicians help ensure the fuel system operates optimally, contributing to the overall health and efficiency of the vehicle.

The fuel system in a vehicle is a critical component responsible for storing, supplying, and delivering fuel to the engine. It comprises various parts working together to ensure efficient combustion and optimal engine performance:

-

Fuel Tank: This is where the fuel is stored before it's pumped to the engine.

-

Fuel Pump: Located inside the fuel tank, it pumps fuel to the engine under pressure.

-

Fuel Filter: Positioned between the fuel tank and the engine, it removes impurities and contaminants from the fuel before it reaches the engine.

-

Fuel Injectors/Carburetor: Fuel injectors in modern vehicles or carburetors in older ones deliver the correct amount of fuel to the engine's combustion chambers.

-

Fuel Lines: These transport fuel from the tank to the engine.

-

Pressure Regulator: Maintains consistent fuel pressure within the system.

-

Fuel Rail: Distributes fuel to individual injectors in vehicles equipped with a fuel-injected engine.

-

Engine Control Module (ECM)/Engine Control Unit (ECU): Controls fuel injection timing, duration, and other engine parameters.

Here's a more detailed breakdown for each component of the fuel system, along with MT Service & Repair's approach to cleaning and repair:

Fuel Tank:

-

Our thorough inspection of the fuel tank involves checking for rust, corrosion, or damage that could compromise its integrity. We employ leak detection methods and pressure tests to ensure the tank securely holds fuel without any seepage or contamination. If issues are detected, we perform repairs or recommend replacements to maintain the tank's functionality and prevent fuel leaks.

Fuel Pump:

-

Our certified technicians conduct comprehensive tests on the fuel pump, assessing its pressure output and overall functionality. We use advanced diagnostic tools to identify any irregularities or signs of wear in the pump. In cases where the fuel pump exhibits reduced pressure or malfunctions, we replace it with a high-quality, compatible component to ensure consistent and reliable fuel delivery to the engine.

Fuel Filter:

-

Regular inspection and replacement of the fuel filter are crucial aspects of our maintenance routine. We understand the significance of a clean filter in preventing contaminants from reaching the engine. Our team replaces fuel filters at recommended intervals to optimize fuel flow and prevent clogs, thereby maintaining engine performance and efficiency.

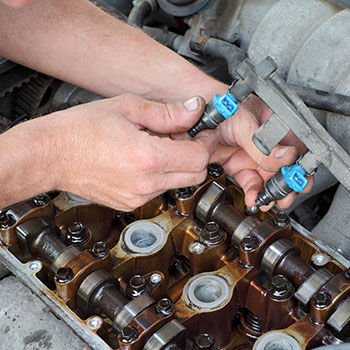

Fuel Injectors/Carburetor:

-

For modern fuel-injected systems, our specialized equipment enables precise cleaning of fuel injectors. We address issues related to clogged or malfunctioning injectors by using advanced cleaning methods that remove deposits, restoring optimal fuel flow and atomization. In older vehicles equipped with carburetors, our experienced technicians conduct meticulous cleanings and repairs to ensure the proper mixing of fuel and air for efficient combustion.

Fuel Lines:

-

Our team inspects fuel lines for signs of wear, leaks, or corrosion. We utilize pressure tests and visual inspections to identify potential issues that could lead to fuel leaks or interruptions in fuel supply. Damaged or deteriorated lines are promptly replaced, and necessary repairs are performed to guarantee consistent fuel flow and prevent hazards.

Pressure Regulator:

-

Ensuring stable fuel pressure is vital for optimal engine performance. Our technicians thoroughly examine the pressure regulator, checking for proper functionality and pressure levels. Any anomalies or signs of pressure irregularities are addressed through repairs or replacements to maintain consistent fuel pressure throughout the system.

Fuel Rail:

-

In fuel-injected systems, the fuel rail's integrity and efficiency are critical. Our team inspects the fuel rail for potential leaks, blockages, or irregularities that may affect fuel distribution. We clean or replace the fuel rail as needed to ensure proper fuel delivery to individual injectors, maintaining consistent engine performance.

Engine Control Module (ECM)/Engine Control Unit (ECU):

-

Our diagnostic expertise involves in-depth assessments of the ECM/ECU using advanced diagnostic tools. We meticulously scan for error codes or irregularities impacting the fuel system's operation. Any issues affecting the ECM/ECU's functionality are diagnosed and resolved to ensure accurate engine control and efficient fuel management.

At MT Service & Repair, we prioritize the meticulous inspection, maintenance, and precise repair of each fuel system component. Our comprehensive approach aims to optimize engine performance, fuel efficiency, and overall vehicle reliability by ensuring a clean, well-functioning fuel system.